Quantitative Pipette Tip Cleaners

Jun 03, 2022

In recent years, quantitative pipettes have been widely used in various experimental operations as a new and ideal precision pipetting instrument. However, the cleaning of pipette tips is manual washing. We design and manufacture a quantitative pipette tip washer based on the principle of the Shanghai blood coagulation plate washer.

1. Production methods

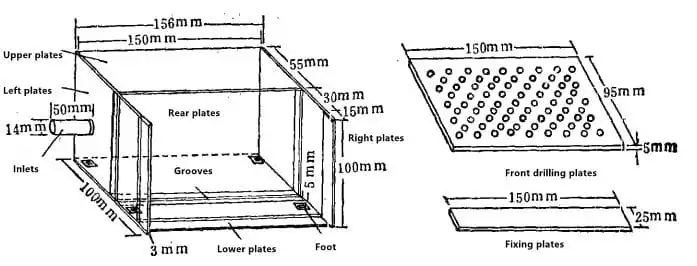

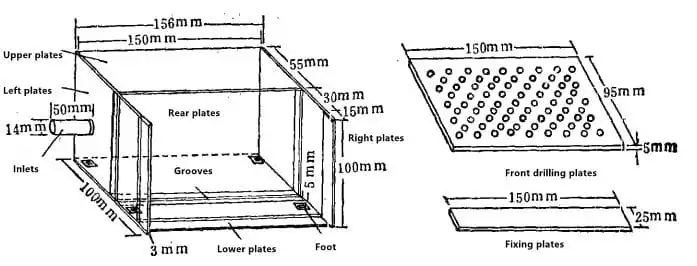

The washer is made of pmma plates, bonded with chloroform, and consists of left and right plates, upper and lower plates, rear plates, movable front drilling plates and fixing plates.

Cut the left and right plates with a size of 100X100mm, the upper plate 150X55mm, the lower plate 150X100mm, and the rear plate 150X90mm. Use chloroform to stick all the plates. At the center of the rear 1/4 of the left plate, drill a circular hole with a diameter of 13mm; put a plastic pipe with a length of 50mm and a diameter of 14mm in hot water to soften it, and quickly insert it into the manhole as a water inlet. Cut 2 strips, and make a groove forward with a width of 5mm at a distance of 45mm from the front edge of the lower plate to fix the lower edge of the front drilling plate. The front drilling plate is 150X95X5mm, as shown in the attached drawing. The diameter of the drilling hole is 5.5mm, and the number of drilling holes is 77. Then, cut 2 pieces of boards of 90X15mm, and stick them to the front edges of the left and right boards. The fixing plate is placed at the gap of the front edge of the upper plate to fix the upper edge of the front drilling plate. The fixing plate is 150X25mm, which is specially used for fixing the drilling plate.

The schematic diagram of each part of the quantitative pipette tip cleaner

2. Usage

Insert the soaked pipette tips into the holes of the front drilling plate, with the thick tip of the tip facing back. Put the lower edge of the front drilling plate into the groove of the lower plate, and the upper edge is closely stuck to the front edge of the upper plate; fix them with a fixed board. Then, connect the water inlet hole with the tap water pipe with a rubber tube to flush. After a few minutes, remove the front drilling plate; rinse the tip twice with distilled water, and then remove the tip. Put it in an incubator with a temperature of 37°C, and let it dry for later use.

3. Advantages

The cleaner replaces manual flushing, which is convenient and practical and can improve work efficiency more than 10 times. The water inlet hole of the washer is big, and the water outlet hole is relatively small, resulting in a great hydraulic pressure difference. Therefore, the washing effect is good. The source of the pmma plate is sufficient, and the cost is not high. If you use leftover materials, it only costs about 4RMB to make one. The structure of the cleaner is simple, and the self-made is not complicated. This cleaner is suitable for the laboratory departments of various hospitals and all units that use pipettes.

1. Production methods

The washer is made of pmma plates, bonded with chloroform, and consists of left and right plates, upper and lower plates, rear plates, movable front drilling plates and fixing plates.

Cut the left and right plates with a size of 100X100mm, the upper plate 150X55mm, the lower plate 150X100mm, and the rear plate 150X90mm. Use chloroform to stick all the plates. At the center of the rear 1/4 of the left plate, drill a circular hole with a diameter of 13mm; put a plastic pipe with a length of 50mm and a diameter of 14mm in hot water to soften it, and quickly insert it into the manhole as a water inlet. Cut 2 strips, and make a groove forward with a width of 5mm at a distance of 45mm from the front edge of the lower plate to fix the lower edge of the front drilling plate. The front drilling plate is 150X95X5mm, as shown in the attached drawing. The diameter of the drilling hole is 5.5mm, and the number of drilling holes is 77. Then, cut 2 pieces of boards of 90X15mm, and stick them to the front edges of the left and right boards. The fixing plate is placed at the gap of the front edge of the upper plate to fix the upper edge of the front drilling plate. The fixing plate is 150X25mm, which is specially used for fixing the drilling plate.

The schematic diagram of each part of the quantitative pipette tip cleaner

2. Usage

Insert the soaked pipette tips into the holes of the front drilling plate, with the thick tip of the tip facing back. Put the lower edge of the front drilling plate into the groove of the lower plate, and the upper edge is closely stuck to the front edge of the upper plate; fix them with a fixed board. Then, connect the water inlet hole with the tap water pipe with a rubber tube to flush. After a few minutes, remove the front drilling plate; rinse the tip twice with distilled water, and then remove the tip. Put it in an incubator with a temperature of 37°C, and let it dry for later use.

3. Advantages

The cleaner replaces manual flushing, which is convenient and practical and can improve work efficiency more than 10 times. The water inlet hole of the washer is big, and the water outlet hole is relatively small, resulting in a great hydraulic pressure difference. Therefore, the washing effect is good. The source of the pmma plate is sufficient, and the cost is not high. If you use leftover materials, it only costs about 4RMB to make one. The structure of the cleaner is simple, and the self-made is not complicated. This cleaner is suitable for the laboratory departments of various hospitals and all units that use pipettes.

Previous: How to Deal with Fogging of Medical Goggles?

Next: Pipettes