Automatic Packaging Systems for Pipette Tips

Oct 24, 2022

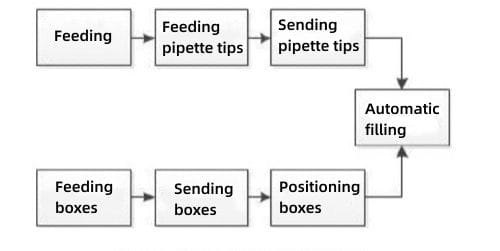

To complete the automatic packaging of the pipette tips, it is necessary to analyze the process requirements for the automatic packaging. First, it is necessary to complete the automatic feeding of the pipette tip and the box, and then insert the pipette tip into the hole in the box to complete the action. Figure 1 shows the flow chart of the process of the pipette tip box, which is as follows:

(1) Disperse the accumulated pipette tips.

(2) The pipette tip should be kept with the big head facing upward and the small head facing downward.

(3) Put the sorted pipette tips into the packaging module.

(4) Adjust the spacing between two adjacent pipette tips to be consistent with the spacing between the holes on the box.

(5) Put the pipette tip on the packaging station accurately and smoothly into the box hole.

Figure 1 The process flow chart of the pipette tip box

When the pipette tip’s packaging process is determined, it is relatively easy to determine the overall scheme of the automatic packaging system. In general, a complete set of automatic packaging systems is mainly composed of automatic feeding devices, displacement mechanisms, automatic packaging devices and supply systems.

1.1 Technical requirements for automatic packaging

To complete the automatic packaging process of pipette tips, a complete set of automatic organizers for the pipette tip is essential. For mechanical devices that can achieve certain functional requirements, there are some necessary normative technical requirements, such as high boxing efficiency, high precision and high intelligence.

Specific requirements are as follows:

(1) High efficiency: the average time is 70 seconds per box.

(2) Good reliability: the error rate of the entire system is less than 5%.

(3) Good versatility: can be used for pipette tips with different sizes.

(4) High degree of intelligence: the entire packaging process is fully automated with simple manual operations.

(5) Long service life: the automatic packaging system can be used daily, and the stability and accuracy of the movement can be ensured. It has a long service life.

1.2 Other requirements for automatic packaging

The design of the automatic packaging system should be advanced and economical with high work efficiency, safety and reliability, and generally should have the following requirements:

(1) The automatic packaging system must have high production efficiency, low energy consumption, less auxiliary operations, and high accuracy during work to achieve complete automation.

(2) The automatic packaging system should be able to reduce labor intensity, meet requirements for ergonomics, operate at an appropriate height, and be simple and safe.

(3) The design of the automatic packaging system should leave room for development and improvement. When the system needs to be improved to achieve new functions, the entire packaging system will not need to be abandoned.

(4) The whole process needs to be hygienic and clean, especially the mechanism that is in direct contact with the pipette tip and avoid manual contact to prevent the pipette tip from being polluted.

(5) The whole system has a simple structure and is easy to operate; the size should be right and can be placed on a laboratory operating table; it should be easy to manufacture and has low costs.

1.3 Overall layout design of the system

After the process flow of the packaging system is determined, the overall equipment layout of the system needs to be carried out, that is, according to the principle of economy and practicality, the arrangement and layout of the automatic packaging system for pipette tips can be effectively solved. On the premise of meeting the functional requirements, the overall layout of the system must realize the rational arrangement of resources, and strive to achieve the effect of convenient operation and maintenance, compact layout, beautiful appearance to achieve good economic benefits.

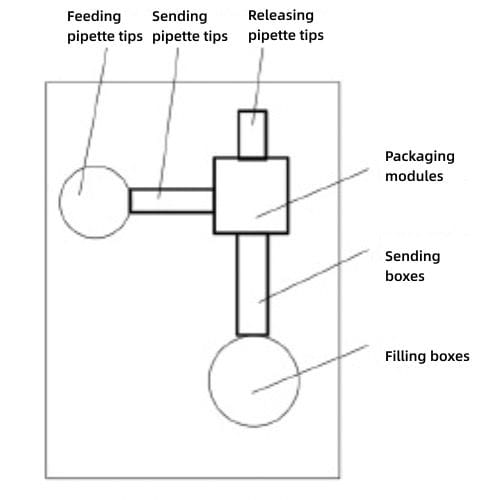

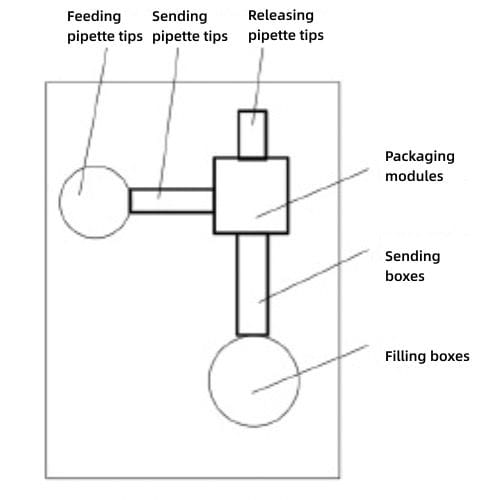

As shown in Figure 2, this layout is similar to the L-shaped layout in the intermittent transfer of equipment. The arranging and feeding module of the pipette tip is arranged vertically with the box body feeding module, and a packaging module is arranged at the intersection. This layout has the advantages of compact structure, small areas, simple control operation, and high positioning accuracy. There are few packaging stations for pipette tips. Choosing this equipment layout is also conducive to the overall control, troubleshooting and daily maintenance of the equipment.

Figure 2 The overall layout of the packaging system

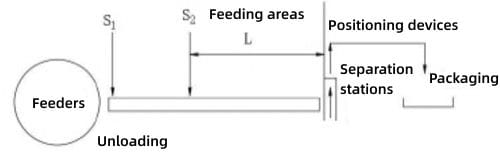

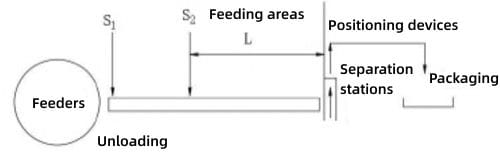

Figure 3 shows the layout of the tip’s feeding area. In the design, two sensors must be installed on the discharge rail, and the working condition of the feeder and the discharge rail is recorded by the sensor S1. If the discharge rail is fully loaded, it is detected by the sensor S1, and the feeder will be powered off to stop feeding. The second sensor S2 activates the hopper and should be able to record the buffer between the feed area and the separation station. The length of the discharge rail should be designed so that it can maintain a buffer capacity of 1 minute. If the part recorded by sensor S2 does not reach this position, this situation is transformed into an audible or optical warning signal.

Figure 3 The layout of the feeding area

(1) Disperse the accumulated pipette tips.

(2) The pipette tip should be kept with the big head facing upward and the small head facing downward.

(3) Put the sorted pipette tips into the packaging module.

(4) Adjust the spacing between two adjacent pipette tips to be consistent with the spacing between the holes on the box.

(5) Put the pipette tip on the packaging station accurately and smoothly into the box hole.

Figure 1 The process flow chart of the pipette tip box

When the pipette tip’s packaging process is determined, it is relatively easy to determine the overall scheme of the automatic packaging system. In general, a complete set of automatic packaging systems is mainly composed of automatic feeding devices, displacement mechanisms, automatic packaging devices and supply systems.

1.1 Technical requirements for automatic packaging

To complete the automatic packaging process of pipette tips, a complete set of automatic organizers for the pipette tip is essential. For mechanical devices that can achieve certain functional requirements, there are some necessary normative technical requirements, such as high boxing efficiency, high precision and high intelligence.

Specific requirements are as follows:

(1) High efficiency: the average time is 70 seconds per box.

(2) Good reliability: the error rate of the entire system is less than 5%.

(3) Good versatility: can be used for pipette tips with different sizes.

(4) High degree of intelligence: the entire packaging process is fully automated with simple manual operations.

(5) Long service life: the automatic packaging system can be used daily, and the stability and accuracy of the movement can be ensured. It has a long service life.

1.2 Other requirements for automatic packaging

The design of the automatic packaging system should be advanced and economical with high work efficiency, safety and reliability, and generally should have the following requirements:

(1) The automatic packaging system must have high production efficiency, low energy consumption, less auxiliary operations, and high accuracy during work to achieve complete automation.

(2) The automatic packaging system should be able to reduce labor intensity, meet requirements for ergonomics, operate at an appropriate height, and be simple and safe.

(3) The design of the automatic packaging system should leave room for development and improvement. When the system needs to be improved to achieve new functions, the entire packaging system will not need to be abandoned.

(4) The whole process needs to be hygienic and clean, especially the mechanism that is in direct contact with the pipette tip and avoid manual contact to prevent the pipette tip from being polluted.

(5) The whole system has a simple structure and is easy to operate; the size should be right and can be placed on a laboratory operating table; it should be easy to manufacture and has low costs.

1.3 Overall layout design of the system

After the process flow of the packaging system is determined, the overall equipment layout of the system needs to be carried out, that is, according to the principle of economy and practicality, the arrangement and layout of the automatic packaging system for pipette tips can be effectively solved. On the premise of meeting the functional requirements, the overall layout of the system must realize the rational arrangement of resources, and strive to achieve the effect of convenient operation and maintenance, compact layout, beautiful appearance to achieve good economic benefits.

As shown in Figure 2, this layout is similar to the L-shaped layout in the intermittent transfer of equipment. The arranging and feeding module of the pipette tip is arranged vertically with the box body feeding module, and a packaging module is arranged at the intersection. This layout has the advantages of compact structure, small areas, simple control operation, and high positioning accuracy. There are few packaging stations for pipette tips. Choosing this equipment layout is also conducive to the overall control, troubleshooting and daily maintenance of the equipment.

Figure 2 The overall layout of the packaging system

Figure 3 shows the layout of the tip’s feeding area. In the design, two sensors must be installed on the discharge rail, and the working condition of the feeder and the discharge rail is recorded by the sensor S1. If the discharge rail is fully loaded, it is detected by the sensor S1, and the feeder will be powered off to stop feeding. The second sensor S2 activates the hopper and should be able to record the buffer between the feed area and the separation station. The length of the discharge rail should be designed so that it can maintain a buffer capacity of 1 minute. If the part recorded by sensor S2 does not reach this position, this situation is transformed into an audible or optical warning signal.

Figure 3 The layout of the feeding area

Previous: Packaging of Pipette Tips

Next: Matters Needing Attention When Purchasing Pipette Tips